In recent years, solution pumps have emerged as pivotal components in various industrial applications, significantly enhancing operational efficiency. According to a report by the International Pumps Market Research Group, the global demand for solution pumps is expected to reach $12.5 billion by 2025, driven by advancements in technology and increasing automation across sectors such as chemical processing and water treatment. These pumps not only facilitate the transportation of fluids but also contribute to sustainability efforts by optimizing resource consumption and minimizing waste. As industries continue to embrace innovative solutions, understanding the functionality and applications of solution pumps becomes essential. This article delves into the innovative uses of solution pumps and provides efficiency tips to maximize their performance, empowering businesses to unlock their full potential in a competitive market.

Solution pumps, particularly positive displacement (PD) pumps, have become integral in various industries due to their efficiency and reliability in handling diverse fluid properties and flow rates. Understanding the functionality of these pumps begins with grasping the basics of their design. PD pumps operate by trapping a fixed amount of fluid and forcing it into the discharge pipe, which allows them to manage flow rates from less than 1 gallon per minute (gpm) to impressive numbers like 15,000 gpm. They are capable of generating pressures ranging from a few psi to over 70,000 psi, making them suitable for high-demand applications such as chemical processing, oil extraction, and even the sophisticated hydraulic systems in Formula 1 cars.

The hydraulics of PD pumps are governed by fundamental physical principles, including pressure and fluid dynamics. Their unique ability to maintain a consistent flow rate regardless of changes in discharge pressure sets them apart from other pump types. This characteristic enables them to be used effectively in systems requiring precise fluid control, thereby enhancing overall operational efficiency. Understanding these core functionalities equips users to leverage the full potential of solution pumps, opening the door to innovative applications across a myriad of sectors.

Solution pumps have emerged as pivotal components across various industries, driving innovation and enhancing operational efficiency. In the recent landscape, data centers are increasingly relying on advanced cooling solutions, particularly liquid cooling systems, to manage the growing demands of AI and cloud computing technologies. These innovative applications not only ensure optimal performance but also contribute to a greener environment, showcasing the power of efficient cooling methods within the tech sector.

Moreover, the maritime industry is undergoing a significant transformation with the introduction of groundbreaking fuel pump solutions for liquefied gases and other sustainable fuels. This shift not only promotes environmental sustainability but also aligns with global efforts to reduce carbon emissions. By adapting to new applications and technologies, solution pumps are proving to be critical in facilitating industry advancements and eco-friendly practices across various fields, from data management to maritime logistics.

The optimization of solution pump performance is crucial as industries strive for enhanced efficiency and sustainability. Emphasizing advanced materials such as corrosion-resistant and wear-resistant options can significantly improve pump longevity and reliability. For instance, the global market for industrial pump control systems, valued at $5 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 5.5%, reaching approximately $8.8 billion by 2030. Adopting innovative material technologies could directly influence this growth, providing better performance in demanding applications.

Moreover, the oil and gas pump market demonstrates another vital application of optimized solution pumps, where the right choice of materials affects the efficiency of fluid movement across various value chain stages. Critical pump types, including centrifugal and positive displacement pumps, show an increasing trend in adoption as industries seek to maximize efficiency. Reports indicate that by 2031, the demand for these pumps will surge, reflecting the need for enhanced performance and increased operational reliability. Thus, focussing on innovative applications and efficiency upgrades can unlock substantial advantages in operational capacities across numerous sectors.

Solution pumps are essential in various industrial applications, yet operators often encounter challenges that can hinder their efficiency. Common issues include cavitation, improper sizing, and maintenance neglect. Cavitation, the formation of vapor bubbles within the pump, can lead to significant damage and decreased performance. To counter this, it is crucial to ensure that the pump operates above its Net Positive Suction Head (NPSH) requirements and to monitor the system for any fluctuations in pressure that may lead to instability.

Another significant challenge is the correct sizing of solution pumps. An oversized pump can lead to increased energy consumption and wear, while an undersized one may fail to meet the necessary flow rates. To avoid these pitfalls, thorough system assessments and calculations should be conducted before installation. Additionally, regular maintenance is key to ensuring longevity and optimal performance. Implementing routine checks on seals, bearings, and impellers can significantly reduce downtime and unexpected repair costs, ensuring that solution pumps remain efficient and reliable in their operations.

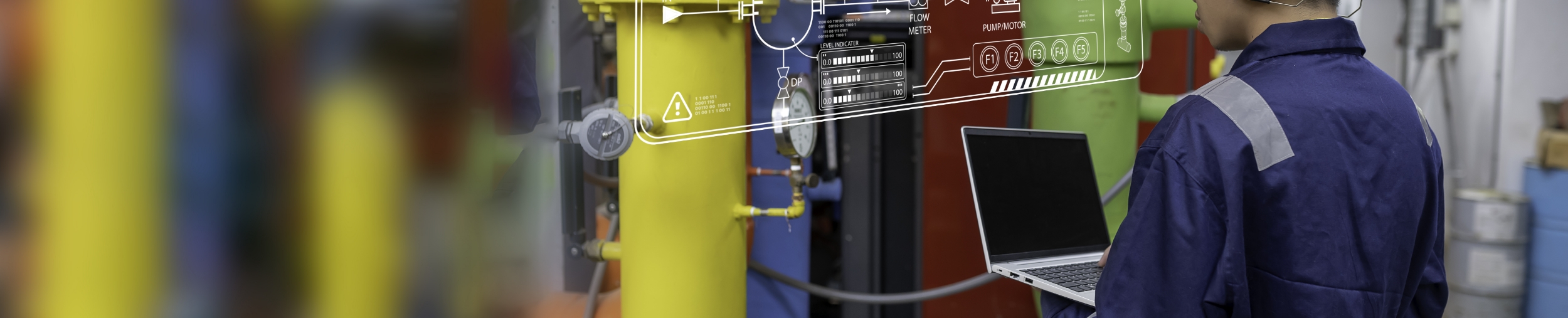

The global market for smart and intelligent pumps is projected to reach $1.72 billion by 2025, with a compound annual growth rate (CAGR) of 7.5% expected through 2034. This growth highlights the increasing adoption of advanced pump technologies that enhance efficiency and operational performance across various sectors, including residential applications. Innovations such as real-time monitoring systems and automated controls are paving the way for more efficient water management solutions.

Future trends in solution pump technology indicate a significant shift toward sustainability and smart integration. As industries prioritize energy savings and minimal environmental impact, the development of energy-efficient pumps and systems that can be integrated with IoT devices is on the rise. Additionally, research into advanced materials and designs is set to improve the longevity and reliability of pumps, further driving the market growth. With these advancements, the potential for solution pumps to revolutionize various industries, from swimming pool equipment to semiconductor processing, is immense.

| Application Area | Pump Type | Efficiency Rating (%) | Innovative Features | Future Trends |

|---|---|---|---|---|

| Water Treatment | Diaphragm Pumps | 85 | Self-priming, corrosion-resistant | Smart monitoring systems |

| Food Processing | Peristaltic Pumps | 90 | Hygienic design, easy cleaning | Sustainability features |

| Chemical Processing | Gear Pumps | 78 | High precision, variable speed | Integration with IoT |

| Petroleum Industry | Centrifugal Pumps | 80 | Durable, high flow rate | Advanced materials for better longevity |

| Pharmaceuticals | Vane Pumps | 88 | Gentle pumping action | Automation in production lines |

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.