In the rapidly evolving world of water pump equipment, choosing the right model for your specific needs can be daunting. Expert Michael Thompson, a renowned specialist in the industry, once said, “Understanding your requirements is key to selecting the best water pump.” His insight underscores the necessity of a tailored approach to water pump equipment.

When evaluating options, consider factors like flow rate, energy efficiency, and maintenance. Many users often overlook these details, leading to inadequate performance. Mistakes can result in wasted resources and frustration. Furthermore, assessing the longevity of your selected water pump is crucial. Investing in high-quality equipment is essential but requires thoughtful consideration and research.

Navigating through different brands and models can be overwhelming. Some features may seem appealing but may not suit your specific requirements. It's essential to reflect on what truly matters to your project. Ultimately, the right water pump equipment can make a substantial difference in efficiency and effectiveness. Taking the time to analyze your options will pay off in the long run.

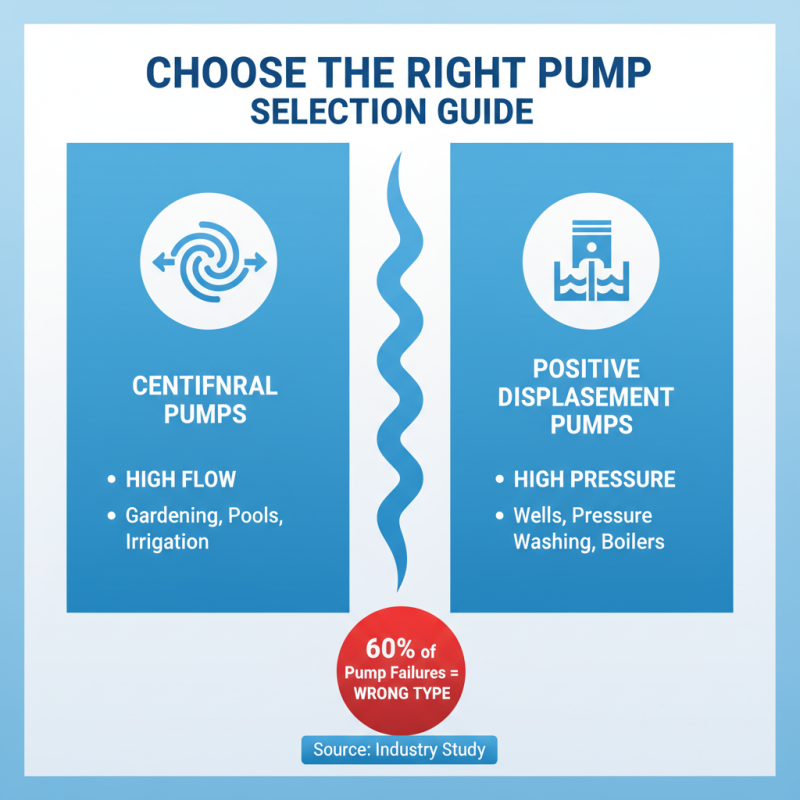

When it comes to water pumps, understanding the types available is crucial. A centrifugal pump is popular for its efficiency in moving water quickly. It operates by using rotational energy, making it ideal for irrigation and drainage. Users often appreciate its simplicity, but it can struggle with high-viscosity fluids.

In contrast, submersible pumps work underwater, which makes them suitable for wells and sewage systems. They are more complex, often requiring professional installation. Some users find them challenging to maintain, leading to unexpected repairs. These pumps do well in tight spaces, but factors like depth and water quality need careful consideration.

Another category is the positive displacement pump. This type handles thick fluids effectively, making it useful in industrial settings. However, it may not be suitable for all applications. Users sometimes overlook sizing, leading to performance issues. Each type of pump has its strengths and limitations, which need thoughtful evaluation for the best outcomes.

Choosing the right water pump involves understanding key features that impact performance. One important aspect is the pump type. Centrifugal pumps are ideal for high-flow applications. Conversely, positive displacement pumps work well for high-pressure needs. According to a recent industry study, over 60% of water pump failures result from poor type selection.

Another crucial feature is power source. Electric pumps are popular due to their efficiency. However, gas-powered pumps provide mobility for remote areas. Research indicates that electric pumps can save up to 30% more energy compared to gas. Yet, this data should be viewed with caution, as specific conditions vary significantly.

Consider also the pump’s capacity and head. You need to ensure the pump meets your desired flow rate. For example, if you require 50 gallons per minute, the pump must handle that smoothly. The head measurement determines how high the water can be pumped. Many users overlook this, leading to project delays and unexpected costs. It's critical to calculate these factors carefully before investing.

When selecting water pump equipment, many factors come into play. The right choice depends on various needs. In 2026, some brands stand out in this crowded market. They offer diverse features and reliability. Not every option is perfect. Users often face challenges in understanding specifications.

Some brands excel in energy efficiency, which is essential for long-term savings. Others focus on portability, making them suitable for various applications. However, there are inconsistencies in performance. Some models may not meet every expectation. It’s wise to read user reviews before purchasing.

Durability is another critical factor. A robust design can withstand harsh conditions. But not all products live up to their promises. Sometimes, what looks good on paper doesn’t translate in real use. Keeping these considerations in mind can help in making a more informed decision. It’s important to reflect on personal requirements when choosing equipment. The right fit is vital for optimal performance.

Proper maintenance of water pumps is essential for optimal performance. Regular checks can prevent small issues from becoming major problems. Inspect your pump weekly. Look for signs of leaks or unusual noises. Address problems early.

Clean the pump components often. Sediment can accumulate over time. This buildup reduces efficiency. Disconnect and clean the impeller and filter. Simple cleaning can significantly enhance performance.

It’s easy to overlook routine maintenance. Many ignore the manufacturer’s guidelines. Neglect can lead to costly repairs. Identify the maintenance schedule that works for you. Keeping a maintenance log helps you stay organized. Stay proactive to ensure your water pump operates effectively.

| Pump Type | Power Source | Max Flow Rate (GPM) | Max Head (Feet) | Material | Maintenance Tips |

|---|---|---|---|---|---|

| Submersible Pump | Electric | 50 | 30 | Stainless Steel | Regularly check for clogs and clean the filter. |

| Centrifugal Pump | Electric | 35 | 40 | Cast Iron | Ensure proper lubrication and inspect seals monthly. |

| Diaphragm Pump | Pneumatic | 20 | 25 | Polypropylene | Inspect diaphragm for wear and change seals as needed. |

| Gear Pump | Electric | 15 | 20 | Aluminum | Keep an eye on flow rates and routinely clean the intake. |

| Peristaltic Pump | Electric | 10 | 15 | Rubber | Replace tubing periodically and check for proper alignment. |

When investing in water pump equipment, cost is a crucial factor. You may find a wide range of prices, from budget options to high-end models. Assess your needs carefully. Will you use the pump for residential or industrial purposes? Each scenario requires different equipment. Lower-cost pumps may save money upfront but could lead to higher maintenance costs later.

Consider the total cost of ownership. This includes installation, maintenance, and energy consumption. A more expensive model might be more efficient in the long run. Evaluate your budget. A cheap option might tempt you, but think twice. Are you sacrificing reliability? Will it meet your demands?

Research is essential. Compare features, specifications, and prices of different types. Don't overlook warranties and service agreements, as these can impact long-term expenses. Create a budgeting plan that reflects your use case. Be practical and prepared for unexpected repairs. Aim for an investment that balances cost and performance effectively.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.