Choosing the right pump for pumping out water can be a daunting task. According to a recent report by the Water Pumping Association, improper pump selection can lead to inefficiency and increased costs. Experts emphasize the importance of understanding your specific needs. John Smith, a renowned hydrology expert, stated, “Selecting the right pump for pumping out water can save you both time and money.”

Many factors influence your pump choice. The water's depth, the flow rate, and the total head measurement are key elements. Yet, some users overlook these aspects, leading to potential mistakes. In a survey, 45% of participants admitted they didn’t consider all variables when selecting their pump. This oversight may result in inadequate performance.

Understanding your environment is essential. In some cases, users might choose heavy-duty pumps for light tasks. This can cause unnecessary wear and tear. Alternatively, an underpowered pump might struggle with larger jobs, leading to frustration. Balancing efficiency and capability is crucial when selecting a pump for pumping out water.

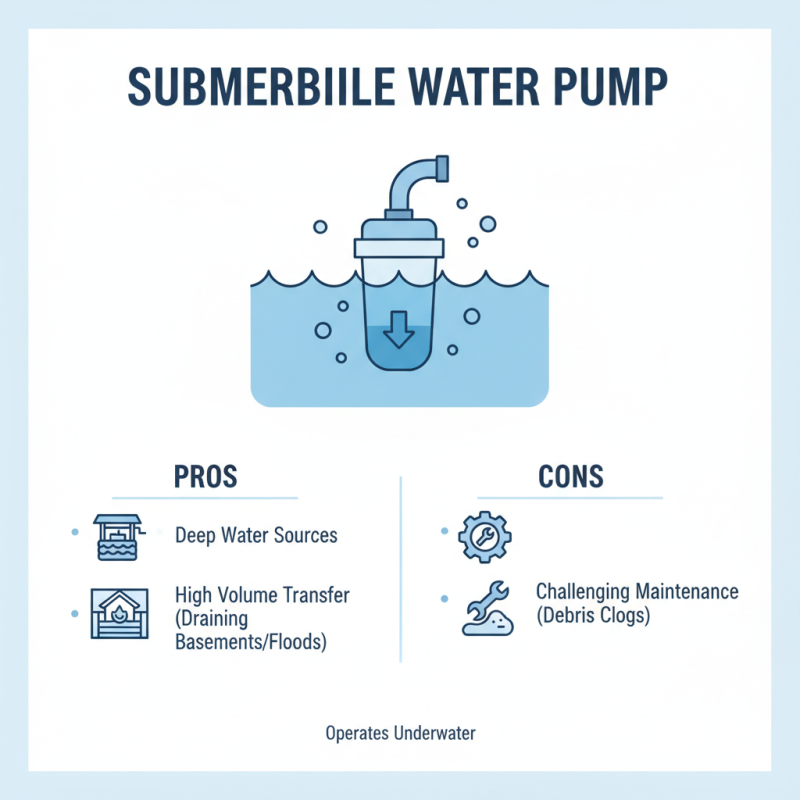

When choosing a water pump, understanding the various types available is crucial. Submersible pumps are ideal for deep water sources. These pumps operate underwater and can efficiently handle large volumes. They're great for draining basements or flooded areas. However, they can be challenging to maintain, especially if debris clogs the mechanism.

Another option is the centrifugal pump. This type is effective for shallow water. It uses a rotating impeller to move water. It works well for irrigation or transferring water between tanks. Yet, one should consider its limitations. Centrifugal pumps may not perform well in heavy debris or very low water levels.

Lastly, consider diaphragm pumps for more specialized needs. They are great for handling liquids with varying viscosities. These pumps are also capable of working with chemicals. However, they can be slower than other types. Be mindful of your specific requirement before making a choice. Always remember that each type of pump has its strengths and weaknesses. Balancing these elements can lead to better outcomes in your pumping tasks.

When selecting a pump, understanding its capacity and flow rates is crucial. Different tasks require different power levels. For a backyard pond, a smaller pump may suffice. However, large-scale draining needs a more robust solution. Assess your specific requirements thoughtfully.

Consider the amount of water you need to move. Think about the time frame in which you want to achieve this task. A pump's flow rate is often measured in gallons per minute (GPM). Higher GPM ratings indicate faster water displacement. It’s essential to match this to your job’s demands.

You might find discrepancies in pump specifications. Some pumps may advertise high flow rates, but real-world performance can vary. Testing and understanding your environment helps. Don’t hesitate to seek out reviews. Experiences from others can guide you on your journey. Choosing the right pump requires careful contemplation, ensuring it meets unique requirements.

When choosing a pump for water removal, evaluating the power source is critical.

Electric pumps are generally easier to operate. They require a power outlet, making them suitable for indoor and low-volume tasks. However, they may not perform well in remote areas. If power goes out, you could be left stranded.

Gas-powered pumps offer mobility and high power. They can work in places without electricity. This makes them ideal for larger jobs like flood clean-up. However, they need maintenance and refueling. They also produce emissions, which can be a concern.

Consider how much water you need to pump. For small jobs, an electric pump might suffice. For bigger operations, go with gas. Always weigh your options carefully. Remember, the right choice depends on your specific needs and conditions.

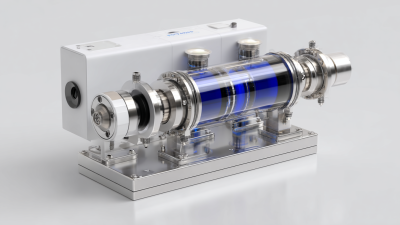

When choosing a pump for water removal, durability and material are crucial. A well-constructed pump can last for years, minimizing long-term costs. Reports suggest that pumps made from corrosion-resistant materials can improve lifespan by 50%. For instance, stainless steel pumps outperform plastic ones in harsh environments. This is vital for users in areas with chemical exposure.

Additionally, consider how the pump's material handles varying temperatures. Pumps designed for high-temperature applications often use specialized alloys, extending their operational life. According to industry studies, pumps that fail due to material fatigue can incur replacement costs up to 30% higher than initial purchases. It’s worth reflecting on the cost of cheap materials. They might seem like a bargain, but the long-term implications are significant. If a pump fails, you might face unexpected downtime and repair costs.

Ultimately, investing in quality materials pays off. Look for pumps with good reviews and data-backed performance. That way, you can make a better choice. Remember, durability is more than just a buzzword; it’s essential for dependable water management.

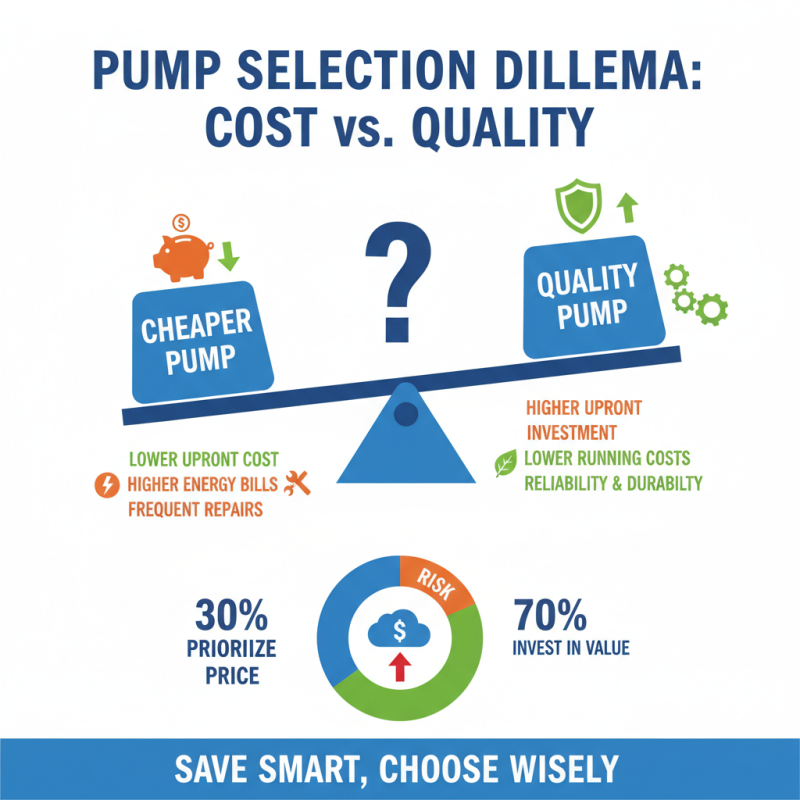

When selecting a pump for water removal, budget considerations are crucial. Many homeowners face the dilemma of balancing cost and quality. Industry surveys reveal that around 30% of individuals prioritize price over performance, often leading to long-term expenses. A cheaper pump may save money upfront, but it can result in higher energy costs and maintenance needs.

Research indicates that investing an extra 25% initially can improve durability. Pumps in the $100-$300 range tend to last longer and perform more efficiently than those costing under $100. On average, quality pumps have a lifespan of about 10 years, whereas budget options may fail within 3-5 years. This reality highlights the importance of understanding value rather than just the sticker price.

Moreover, proper assessment of needs is often overlooked. For example, a pump's flow rate should match specific requirements. High-volume scenarios demand more robust pumps. A mismatch can lead to inefficient pumping, wasting both resources and time. Adopting a long-term perspective can prevent the pitfall of underperformance and frequent replacements in the future.

We are here to help you with all your queries and concerns, just write to us using the below form and we will get back to you as soon as we can.