Ultimate Guide to the Top Axial Flow Pumps: Side-by-Side Comparisons for Optimal Choices

In the realm of fluid dynamics, the Axial Flow Pump plays a crucial role in numerous applications, ranging from water treatment to industrial processes. According to a report from Grand View Research, the global pump market is expected to reach USD 87.78 billion by 2025, with axial flow pumps witnessing significant growth due to their efficiency and reliability in handling large volumes of fluids at relatively low pressures. These pumps are particularly favored for their ability to maintain high flow rates, making them essential in sectors such as agriculture, wastewater management, and chemical processing. In this ultimate guide, we will provide a comprehensive side-by-side comparison of the top axial flow pumps available in the market, helping you make an informed decision that aligns with your operational requirements.

Key Features to Consider When Choosing Axial Flow Pumps

When selecting axial flow pumps, understanding key features can significantly influence operational efficiency and cost-effectiveness. One crucial factor to consider is the pump's hydraulic design, which affects its flow rate and head efficiency. According to a report by the Hydraulic Institute, optimizing these hydraulic parameters can enhance performance by as much as 15% compared to standard designs. Additionally, materials used in manufacturing will impact longevity and maintenance frequency; pumps made of corrosion-resistant alloys can reduce downtime and replacement costs in aggressive environments.

Another important aspect is the pump's operating range. Axial flow pumps are typically chosen for their ability to handle large volumes of liquid at low to medium head with high efficiency. International standards, such as those outlined by the American Society of Mechanical Engineers (ASME), suggest that selecting a pump with a broader operating range can provide users with greater flexibility and adaptability in various applications, including irrigation and sewage treatment. Furthermore, the efficiency rating of axial flow pumps can vary considerably; data indicates that pumps designed specifically for high-capacity, low-energy consumption applications can lead to significant savings on energy costs over time.

Essential Performance Metrics for Optimal Axial Flow Pump Selection

When selecting an axial flow pump, understanding the essential performance metrics is crucial for optimizing your choice. Flow rate, efficiency, and head are the primary metrics to consider. The flow rate defines the volume of fluid the pump can move within a certain period and is measured in cubic meters per hour (m³/h). Selecting a pump with a flow rate that matches your requirements ensures that your system operates efficiently without unnecessary strain on the equipment.

Efficiency, often expressed as a percentage, indicates how effectively the pump converts input power into hydraulic energy. Higher efficiency means lower operational costs and better performance over time. Additionally, evaluating the head, which refers to the height a pump can lift fluid, is vital. It determines how far and high the pump can move a fluid against gravity. By analyzing these metrics, engineers and operators can make informed decisions, ensuring that they invest in an axial flow pump that not only meets their operational needs but also provides longevity and reliability in various applications.

Comparison of Axial Flow Pump Performance Metrics

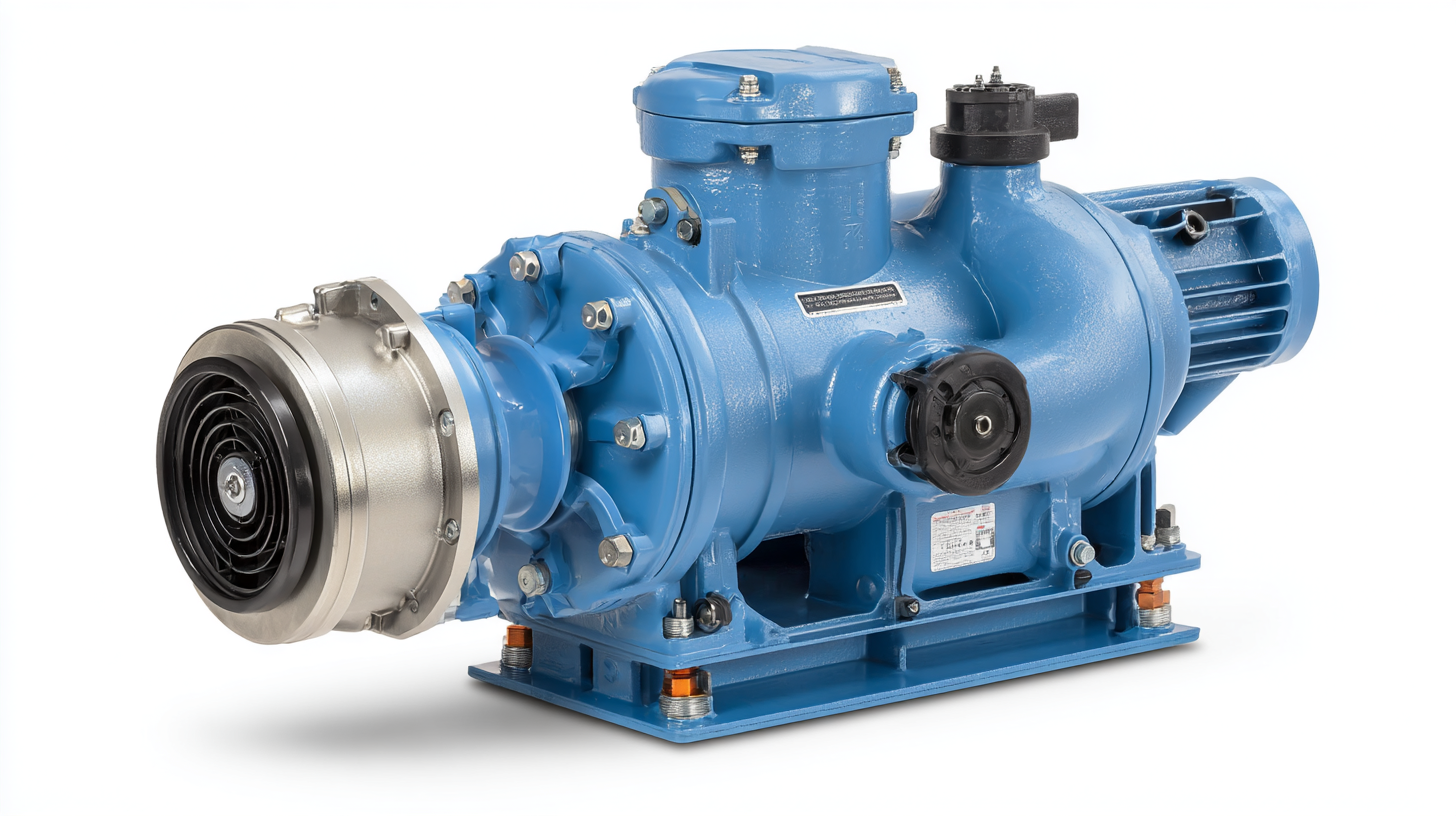

Top Brands Reviewed: Comparing Design and Durability of Axial Flow Pumps

When selecting the best axial flow pumps, the design and durability of top brands are crucial considerations. Recent industry reports indicate that the efficiency of axial flow pumps can vary significantly based on their design features. For instance, pumps with an enclosed impeller design are known to enhance hydraulic efficiency and mitigate wear and tear, leading to longer operational life spans. According to a 2022 market analysis by Global Industry Analysts, the demand for high-efficiency axial flow pumps has surged, as businesses seek to optimize operational performance and reduce energy consumption.

Durability is another key factor when evaluating axial flow pumps. Reports from the Hydraulic Institute suggest that pumps constructed from corrosion-resistant materials can extend service life by 30% or more, particularly in harsh operational environments. Brands like Xylem and Grundfos have emerged as leaders in this space, known for their innovative material use and robust construction. Their advanced designs not only improve functionality but also enhance reliability, making them formidable choices for industries ranging from water treatment to agricultural irrigation. Thus, reviewing these attributes is essential for making informed decisions that align with long-term operational goals.

Ultimate Guide to the Top Axial Flow Pumps: Side-by-Side Comparisons for Optimal Choices

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Flow Rate (GPM) | 500 | 600 | 550 |

| Motor Power (HP) | 10 | 15 | 12 |

| Efficiency (%) | 85 | 90 | 88 |

| Weight (lbs) | 80 | 90 | 85 |

| Material | Cast Iron | Stainless Steel | Bronze |

Cost Analysis: Budgeting for the Best Axial Flow Pumps on the Market

When budgeting for axial flow pumps, it's essential to consider not just the initial purchasing costs but also the long-term operational expenses. According to a 2022 industry report by Grand View Research, the axial flow pump market is expected to reach USD 9.6 billion by 2028, growing at a compound annual growth rate (CAGR) of 4.5%. This growth indicates a rising demand for efficient pumping systems versatile enough for various applications, including water treatment and industrial processes. When comparing options, potential buyers should examine not only the price but also factors such as efficiency ratings and maintenance requirements that can impact overall cost.

For instance, a study from the Hydraulic Institute shows that properly maintained axial flow pumps can achieve efficiency levels of over 85%, significantly reducing energy costs compared to lower efficiency models. Moreover, the initial investment in higher-quality pumps might seem substantial; however, with the potential to save thousands in energy bills annually, they often prove to be the more economical choice in the long run. As you assess your budget, always incorporate not just the upfront cost but the holistic view of lifecycle cost, ensuring that your investment yields optimal performance and savings.

Maintenance Checklist for Ensuring Longevity of Axial Flow Pumps

When it comes to ensuring the longevity of axial flow pumps, a well-structured maintenance checklist is crucial. Regular inspections should begin with checking the mechanical seals and bearings for wear and tear. This is essential, as compromised seals can lead to leaks, while worn bearings may result in excessive vibration and noise, potentially decreasing the pump's efficiency. Additionally, it's vital to monitor the lubrication system; ensuring proper lubrication of moving parts minimizes friction and prolongs the service life of the pump components.

When it comes to ensuring the longevity of axial flow pumps, a well-structured maintenance checklist is crucial. Regular inspections should begin with checking the mechanical seals and bearings for wear and tear. This is essential, as compromised seals can lead to leaks, while worn bearings may result in excessive vibration and noise, potentially decreasing the pump's efficiency. Additionally, it's vital to monitor the lubrication system; ensuring proper lubrication of moving parts minimizes friction and prolongs the service life of the pump components.

Routine cleaning is another critical aspect of maintenance. Accumulation of debris and contaminants can significantly impair the performance of axial flow pumps. Schedule regular cleanings of both the pump's external surfaces and its internal components, particularly the impeller and volute casing. Moreover, conducting periodic performance tests to assess flow rates and pressure can help identify any early signs of deterioration. By following this comprehensive checklist, operators can significantly enhance the reliability and durability of their axial flow pumps, ensuring optimal operational efficiency over time.